Teflon-lined hoses are used to contain coolant – Teflon-lined hoses are a superior choice for coolant containment, offering a unique combination of properties that ensure reliable performance in demanding industrial applications. Their exceptional chemical resistance, corrosion resistance, flexibility, durability, and temperature tolerance make them an ideal solution for handling various coolants.

The use of Teflon as a lining material provides numerous advantages, including its inert nature, which prevents chemical reactions with coolants. Additionally, its non-stick surface minimizes coolant buildup and facilitates easy cleaning, reducing maintenance requirements.

1. Teflon-Lined Hoses

An Overview

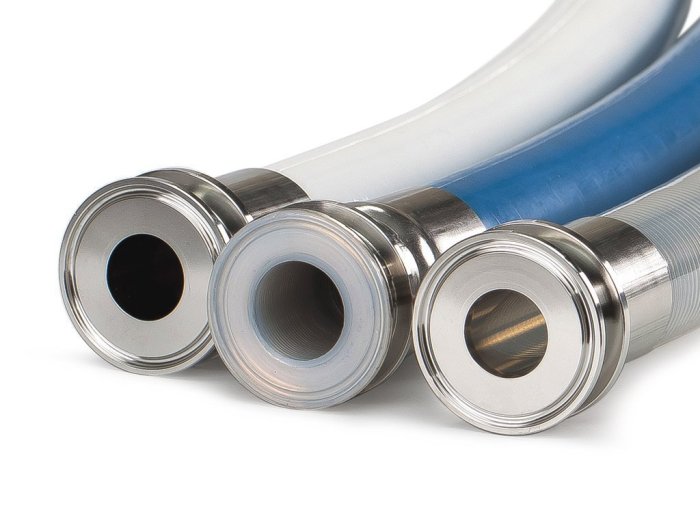

Teflon-lined hoses are flexible conduits used to transport and contain liquids and gases. They consist of an inner core of flexible material, typically a fluoropolymer such as Teflon (polytetrafluoroethylene), encased within a protective outer layer.

Teflon, known for its exceptional chemical inertness, high temperature resistance, and low coefficient of friction, provides a superior lining material for hoses. It offers excellent protection against corrosion, abrasion, and chemical degradation, making Teflon-lined hoses ideal for a wide range of industrial applications.

2. Advantages of Using Teflon-Lined Hoses for Coolant Containment

- Chemical resistance:Teflon’s inert nature makes it highly resistant to most chemicals, including acids, bases, solvents, and oils.

- Corrosion resistance:Unlike metal hoses, Teflon-lined hoses are not susceptible to corrosion, ensuring long-lasting performance even in harsh environments.

- Flexibility and durability:The flexible construction of Teflon-lined hoses allows for easy routing and installation, while their robust design ensures durability in demanding applications.

- Temperature tolerance:Teflon has a wide operating temperature range, from cryogenic temperatures to high heat, making it suitable for use in various industrial processes.

Examples of applications where Teflon-lined hoses are used for coolant containment include chemical processing, pharmaceutical manufacturing, and semiconductor fabrication.

3. Design and Construction of Teflon-Lined Hoses

Teflon-lined hoses are typically constructed using a multi-layer design:

- Inner core:The inner core, which comes into contact with the coolant, is made of a flexible fluoropolymer, such as Teflon.

- Lining thickness:The thickness of the Teflon lining can vary depending on the application requirements and the level of chemical resistance needed.

- Bonding methods:The Teflon lining is bonded to the inner core using specialized techniques, such as extrusion or sintering, to ensure a strong and durable bond.

- Outer layer:The outer layer provides protection and reinforcement to the hose. It can be made of various materials, such as stainless steel, fiberglass, or polymers.

- Fittings and end connections:Teflon-lined hoses are equipped with appropriate fittings and end connections to facilitate their installation and connection to other components.

Illustrations or diagrams can be provided to demonstrate the design and construction features of Teflon-lined hoses.

4. Installation and Maintenance of Teflon-Lined Hoses

Proper installation and maintenance are crucial for the optimal performance and longevity of Teflon-lined hoses:

- Handling and storage:Teflon-lined hoses should be handled and stored carefully to prevent damage to the lining.

- Installation techniques:The hoses should be installed according to the manufacturer’s guidelines, using appropriate tools and techniques.

- Inspection and maintenance schedules:Regular inspections and maintenance, including visual checks and pressure testing, are essential to ensure the integrity and safety of the hoses.

A table summarizing the installation and maintenance steps can be provided.

5. Safety Considerations for Teflon-Lined Hoses: Teflon-lined Hoses Are Used To Contain Coolant

- Chemical compatibility:The chemical compatibility of the coolant with the Teflon lining should be verified to ensure safe operation.

- Temperature limits:Teflon-lined hoses have specific temperature limitations, and exceeding these limits can compromise their integrity.

- Pressure ratings:The hoses should be used within their specified pressure ratings to prevent failure and potential hazards.

Guidelines for safe handling and disposal of Teflon-lined hoses should be provided.

6. Comparison with Other Hose Materials

Teflon-lined hoses offer several advantages over other hose materials commonly used for coolant containment:

- Rubber hoses:Teflon-lined hoses are more resistant to chemicals, corrosion, and high temperatures than rubber hoses.

- Metal hoses:While metal hoses can withstand higher pressures, they are susceptible to corrosion and may not be suitable for all chemical environments.

- Composite hoses:Composite hoses offer a combination of properties, but may not match the chemical resistance and flexibility of Teflon-lined hoses.

A table summarizing the key differences in terms of properties, performance, and cost can be provided.

FAQ Insights

What are the key advantages of using Teflon-lined hoses for coolant containment?

Teflon-lined hoses offer several advantages, including excellent chemical resistance, corrosion resistance, flexibility, durability, and temperature tolerance.

How are Teflon-lined hoses constructed?

Teflon-lined hoses are typically constructed with a durable outer hose material, such as stainless steel or rubber, and a lining of Teflon (PTFE) bonded to the inner surface.

What are some specific applications where Teflon-lined hoses are used for coolant containment?

Teflon-lined hoses are commonly used in various industrial applications, including chemical processing, automotive, and power generation, where reliable coolant containment is crucial.